Home >> Machinery >> Construction Materials & Equipments >> Brick Making Machine >> Details

Clay Brick Making Machine

Clay brick making machine is our featuring product and we've been engaged in brick making machine exporting for many years. Each year, there are numbers of projects concerning our brick making machine finished around the world and our products have already enter regions as africa, middle east, eastern europe and more.

The project adopts shale as the material, once- setting- firing technics, after molding section, the green brick will be dried in the drying room, fired in the tunnel kiln; solid fired brick or brick with hollows will be gotten , adopting natural gas as fuel.

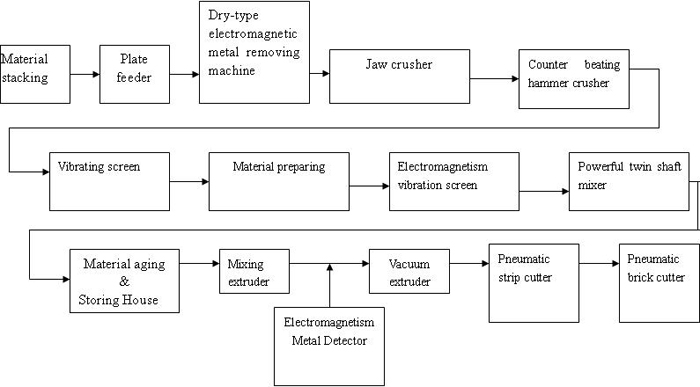

Flow chart of the clay brick making machineries

Brick making machine - Clay preparation

| Equipment Required | ||||

| Plate feeder | Rubber belt conveying machine | Dry-type electromagnetic metal removing machine | Fine jaw crusher | Twin chain scraping board conveyor |

| Disc material feeder | Counter beating hammer crusher | Mechanical vibrating flat hop-pocket dust catcher | Scraping board conveying machine | Electromagnetism vibration high frequency vibrating mesh screen |

| Material preparing machine | Twin shaft mixing machine | Reversible material distributing machine | Hydraulic multi-bucket excavator | Box-type feeder |

| Twin shaft mixing extruder | ||||

Plate Feeder

YG100 Disk Screening Feeding Machine

This machine is mainly used for mixing, preparing and homogenizing materials such as pulverized fuel ash, clay, gangue, shale, etc. and improving the performances of materials. It also has the functions of purifying and screening the materials and is an ideal machine for brick and tile production lines.

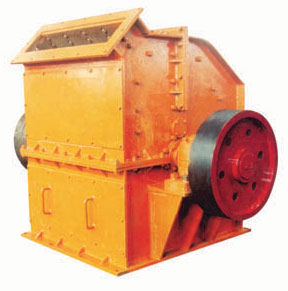

Jaw Crusher

Jaw Crusher is mainly used for crushing raw material to fine particles. The clearance between the two rollers is< 1mm and hardness of the rubber is HRC65-70.The machine is equipped with pneumatic scraper and two semi-automatic grinders.

PN500 reversible material distributing machine

This intermittent feeding machine and evenly distribute the materials to the next process. It is applicable to various bulk and block materials with the feeding speed controllable and feeding quantity adjustable.

Twin Shafts Mixer

This machine is mainly to mix the raw materials such as gangue, shale, clay, etc.

Brick making machine - Molding section

| Equipment list | ||||

| Double grades vacuum brick extruder | Automatic strip cutting machine | Belt conveying machine | Reversing accelerating belt machine | Automatic chamfering green brick cutting machine |

| Green brick overturning machine unit | Green brick conveying incline belt machine | Water circulation type vacuum pump | Screw air compressor | Green brick returning rubber belt conveying machine |

| Green brick returning rubber belt conveying machine | ||||

Pictures of Main Equipments

JZK60/60-40 double grades vacuum brick extruder

JZK60/60-40 Two-stage Vacuum Extruder has the features that its reamer shaft is self-centered without head swing: the service life of non-metal wear resistant bushing can be more than one year; parts of the vacuum box sieve disk unit is easily replaceable; the upper agitator shaft has full protective structure; the reduction gears have hard surface, with powerful extruding force and long service life.

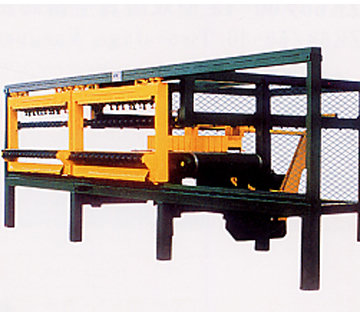

ZQT600*200 auto green brick strip cutter

It performs fully automatic operation, vertical cutting and has two-stage safety protection device. It is a new product at national level.

ZQP24 automatically blank brick cutting machine

It is controlled by programmed controller and performs fully automatic operation. The steel wire is adjustable without stopping the machine. The machine has no mechanical clutch device or sliding, friction and contact parts. The free adjustment of steel wire can satisfy cutting of unfired bricks of different dimensions. It is a new product at national level.

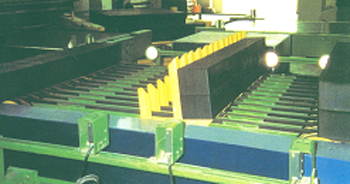

Green brick overturning machine unit

The main use of Green brick overturning machine unit is for green brick conveying, turning, organizing before stacking by auto brick palletizing.

Brick making machine - Tunnel kiln

The tunnel kiln is composed of of furnace body, traction system, rail, kiln-car, and firing system, hot air ventilation system, control system, etc. which has the merits as follows: low cost, small propeller, large load, arched furnace, security, convenient maintenance and so on. The design and manufacture of the tunnel kiln could be negotiated based on customers' request, including chamber dimension, working Temperature, controlling method and number, traction way and speed as well as heating power.

Basically, a brick kiln consists of two main parts. One is drying chamber. The other is tunnel kiln. There is no special burning system for drying chamber. The extra heat used in tunnel kiln will be feedback to drying chamber through a pipe system.

For clay fired brick, if the green brick water content is less than 14%. We adopt same kiln carts for both drying chamber and tunnel kiln.

Tunnel Kiln Plant

Tunnel Kiln Plant

Drying Chamber consists of foundation, drying chamber body, kiln gate, kiln cart, outside hot air feedback pipe system, inside ventilation system .

It is recommended that our buyer to build up foundation,drying chamber body, kiln gate, in local by buyer himself. We will provide complete technical service (site instruction, raw materials list, engineering drawing, etc) and supply necessary main materials (non standard fireproof bricks, special fireproof materials. Non standard steel profiles, etc.)

.

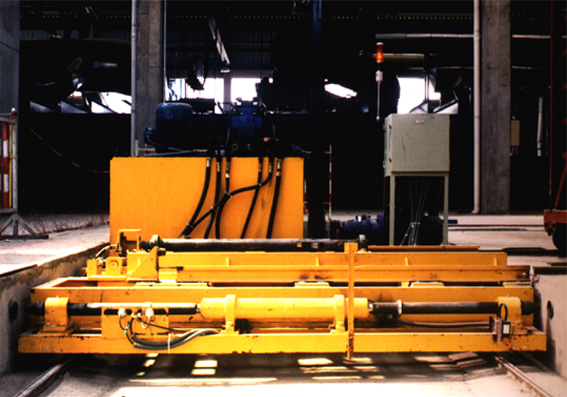

Kiln Cart

Tunnel kiln consists of foundation, kiln chamber body, kiln gate, kiln cart, heat transfering pipe system, inside ventilation system, traction system, temperature control system, natural gas/oil buring system.

YDS-30 the drying room hydraulic vehicle withstanding machine

It is recommended that our buyer to build up foundation, drying chamber body, kiln gate, kiln cart in local by buyer himself. We will provide complete technical service (site instruction, raw materials list, engineering drawing, etc) and supply necessary main materials (non standard fireproof bricks, special fireproof materials. Non standard steel profiles, etc.).

Drying Chamber

Brick Output

Brick making machine - Transmission system

| Equipment Required | |||

| Electric blocks\hoist | Automatic green brick palletizing machine | Automatic brick unloading machine | Auto Brick conveying brick clamp |

| Belt conveying machine | |||

Belt conveyor

Belt conveyor is used in the transmission of sections like Clay Preparation, Molding, Loading & Unloading, etc.

Brick clamper

The brick clamper will be used to discharge fired brick from kiln car orderly.

ZMP Automatic Unfired Brick Stacking Machine

This machine is a mechanical hand for stacking unfired bricks into the kiln car, controlled by programmed controller with pneumatic and mechanical interlock. The clamping force is adjustable and the actions are accurate and reliable.

Brick making machine - Control system

| Equipments Required | ||

| Molding section automatic control | Kiln car operation automatic control | Automatic brick loading& unloading system control |

Controlling Box

Controlling Panel

After saling clay brick making machine, we will send our assembly team to customers' workshop for installation, local workers will also be trained during the installation.

Chinese

Chinese English

English German

German Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korean

Korean Arabic

Arabic Russian

Russian