Home >> Machinery >> Light Industy Machinery >> Can Production Line >> Details

Automation Leak Tester

Automation Leak Tester[10-10-21 14:59:34]

Introduction of Automation Leak Tester

Our Automation Leak Tester is designed by computer-assistant engineering and high technology. The Automation Leak Tester has proven high efficiency, low maintenance and energy-saving during years of practice. The company is engaged in leak test machinery development, production, sales and service.

The product is new generation soap producing machinery based on advanced international technology and many overseas product analysis with optimizing design and high level in domestic market.

The product is new generation soap producing machinery based on advanced international technology and many overseas product analysis with optimizing design and high level in domestic market.

Products Information of Automation Leak Tester

|

|

|

|

|

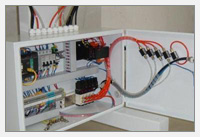

Introduction: Automation Leak Tester is a most current generation of hollow container leak tester researched and developed independently with years of experience in leak testing industry and on the basis of advanced technology. The technology of whole machine leads among the products in the same industry. The testing process adopts a number of patented technologies to ensure that the machine can perform on-line non-destructive testing at high speed, steadily and reliably. The system has several intellectual functions which can meet the special requirements of customers. Being applicable to the leak testing for all kinds of bottles, barrels and kettles, it is an ideal auxiliary equipment for hollow article manufacturers. Features: 1. Reliable, Stable, and High Speed. Based on advanced PLC control technologies. Using high precision pressure transducer(PT), greatly improve inspection precision and reliablility. Provide max 6 channel for each machine, suitable for high speed blowing moulding machine & conveyor; 2. Wide range of check article. Can be used for different articles by simple regulating. 3User interface is personalized design. Touched HMI provides ample system information and operating information. Easy to operate and maintain. Operation panel provides Chinese and English screen; 4. Double-check function. A single machine inspects a product two times, which increased qualified rate of inspected products. Suitable to the leak testing of packing containers for pesticides, chemicals, dangerous substances, etc; 5.Positive and negative bottle kicking logic. To avoid downfallen bottles intermingled with products when pouring bottles; 6. Dynamically tracing the operating parameters of the system. The pressure of each channel during the inspection is displayed with a curve, so the pressure changing in bottle are clear; 7. Check Data Record. The system saves the data on the last 8 inspections for each channel for operators to adjust parameters and improve efficiency; 8.Recipe function. The system provides 25 sets of process parameters for bottle inspection which can be adjusted easily and quickly; 9.Multi-Funtion output port. The system reserves 1~2 multi-funtion output ports which can be randomly designated to a certain DO output; 10. Modular machine design. Solid, durable, and attractive; 11. Material of components are superior, to ensure that the system operates reliably. |

|||

Chinese

Chinese English

English German

German Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korean

Korean Arabic

Arabic Russian

Russian