|

|

|

As environmental protection attached more attentions nowadays, paper products which is resolvable, reclaimable and can be repeatly used are taking the place of foaming and plastic products which results in "white pollution".CLIMA pulp molding machine takes waste paper as the raw material, throught milling, forming, drying and other procedures and finally manufactures into environmental protection paper table wares and other paper products which can take replace foaming and plastic products.

Practical application: Protective packaging for electronic goods, toys, cosmetics, pro-product for computers, personal computer parts, small home appliances, acoustic products, medical goods, automobile parts, hand and pneumatic tools, glass, pottery and porcelain goods, and application in making lunch boxes.

|

|

All data below are only for your reference, we can adjust the specificaiton according to you requirement.

Paper pulp making system

|

Pulp making is the first procedure of paper pulp mould products.

Hydraulic pulp crusher is the main equipment of pulp making system, stirring and crushing the raw materials (water paper or original pulp plate) with hydraulic force, then mixing it into the water and forming pulp which satisfies the shaping requirement of paper pulp mould.

The standard hydraulic pulp crusher consist of: 0.4m3, 0.8m3, 1m3, 1.5m3~2.5m3, the motor power ranges 7.5~22KW.

We are capable of providing equipment of other specification and full stainless steel case equipment catering to customer's demands.

Shaping machine vacuum system

Under the negative pressure, the shaping machine absorbs the pulp to form the primary paper mould. The vacuum system generates and remains regulated negative pressure with vacuum pump and vacuum negative pressure tank system.

At present, the varieties of the vacuum system consist of: the shaping machine applies small negative pressure tank , separate vacuum system; and several shaping machines using one large negative tank , using central vacuum system.

The central vacuum system matches several shaping machine with one set of vacuum device, it boasts of concentrated control, high efficiency and convenient operation and control.

|

|

Shaping system

|

|

Paper pulp products shaping machine is a kind of equipment to form paper cushion wet embryo, it absorbs the paper pulp on the mould and shapes it into regulated shapes.

After absorbing the abroad advanced technology, our company has designed and developed the paper pulp mould shaping machines which boast of advanced technology, reasonable structure, fine performance, stable quality and fine economic benefit.

The new generation shaping machine applies advanced microcomputer and PLC technology as well as intelligent touch screen operation and control system, It has the function of largely improving the working efficiency and the integrated performance. The machine boasts of high working precision, convenient and simple operation as well as intelligent adjusting mould.

Our shaping machine products consist of: reciprocating single tank double work station 、Single tank double work station, double tank duplex station shaping machine, returning shaping machine and fully automatic shaping machine.

Basic technical index to the shaping machine

|

Spec. |

Case amterial |

Template Size |

Working Cycle s/times |

Control method |

Vacuum degree MPa |

|

Single tank single work station |

Stainless steel |

600 × 660 |

10~60 adjustable |

PLC |

-0.05~-0.07 |

|

Single tank duplex station |

Stainless steel |

1070 × 660 |

10~60 adjustable |

PLC |

-0.05~-0.07 |

|

Double tank duplex station |

Stainless steel |

500 × 660 × 2 |

10~60 adjustable |

PLC |

-0.05~-0.07 |

|

Returning shaping machie |

Stainless steel |

1000 × 660 |

10~60 adjustable |

PLC |

-0.05~-0.07 |

|

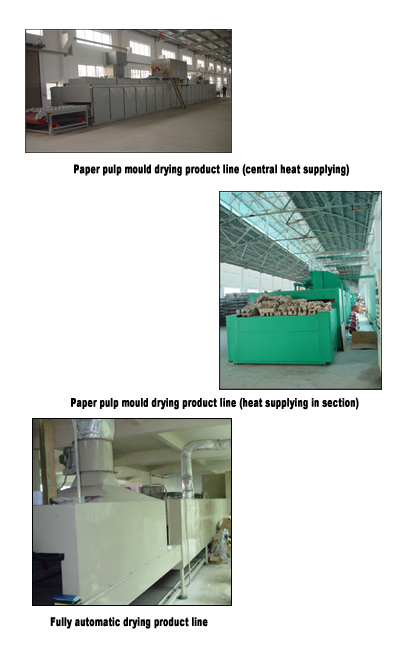

Drying system

|

Our oil(gas) drying product lines apply central heat supplying which is the first time to break the designing habit of burning in section in abroad. The machine boasts of stable drying temperature, high heat efficiency, high integrated degree. Moreover, it features perfect advantages in energy consumption and production. The product has been issued the state patent certificate. Many merchants from Japan and Philippines have purchased our products.

Applying concentrated electric control, all the apparatus and parts are installed in one electric control box, the temperature measuring device is installed in the heating room, the temperature in the heating area may be set to the required level only by adjusting the heating room air door.

Applying digital temperature apparatus, high precision and reliable.

Applying stepless conveying device, with the combination of quality industrial chains, the linear velocity of the product line achieves stepless speed regulation.

Our drying product line heat source consists of: oil (gas), steam, oil/steam, coal, wood, heat conduction heating etc.

The belt width consists of 1.4m, 1.8m, 2m; and the belt length consists of 24m, 30m, 38m and 45m.

We are also capable of designing and manufacturing non standard equipment catering to client's demands.

Basic technical index of drying product line

|

Spec. |

Belt width m |

Belt length m |

Working Temperature ℃ |

Heat power ( KW ) |

evaporation capacity ( kg/h ) |

|

24m × 1.4m |

1.4 |

24 |

80~230 |

250~400 |

140~220 |

|

38m × 1.4m |

1.4 |

38 |

80~230 |

400~800 |

200~350 |

|

30m × 2m |

2.0 |

30 |

80~230 |

450~850 |

250~400 |

|

38m × 2m |

2.0 |

38 |

80~230 |

500~1000 |

350~500 |

|

45m × 2m |

2.0 |

45 |

80~230 |

600~1200 |

400~600 |

|

|

Foaming System

|

|

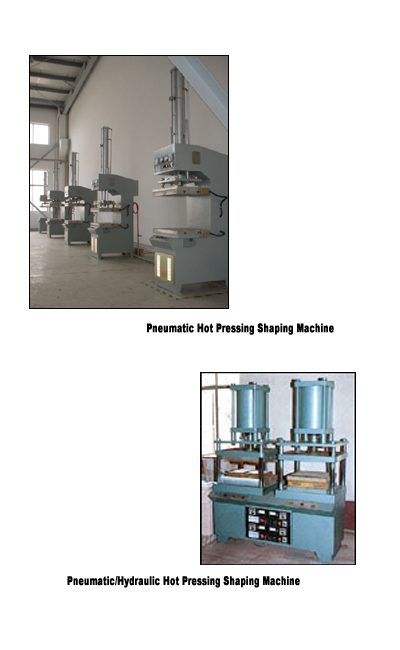

After baking and drying, the paper pulp mould product will distort, the hot pressing shaping machine is the machine to shape the paper tray products and enhance the toughness.

Paper pulp mould hot pressing shaping machine is a kind of equipment to shape the drying paper tray products under high temperature and high pressure. After treated by the machine, the paper tray products boast of fine anti-shocking performance and fine appearance.

Our hot pressing shaping machines consist of 1 ton, 3 tons, 5 tons, 8 tons and 10 tons. They have varied working pressure and working travel and are capable of satisfying the requirements of different paper tray products.

The methods of driving consists of: pneumatic, hydraulic and pneumatic/hydraulic etc.

Basing on the traditional pneumatic or hydraulic equipment, our company has developed a new generation pneumatic/hydraulic hot pressing machine which features fine working pressure and saving energy.

Basic Technical Index to the Shaping Machine

|

Spec. |

Template Size |

Working Cycle s/times |

Power (KW) |

Nominal Pressure ( tons ) |

Working Temperature ( ℃ ) |

Air Source Pressure MPa |

|

1 tons ( pneumatic ) |

560 × 430 |

10~60 adjustable |

6 |

1 |

Room temperature ~180 adjustable |

0.5~0.6 |

|

3 tons ( pneumatic ) |

650 × 450 |

10~60 adjustable |

7 |

3 |

Room temperature ~180 adjustable |

0.5~0.6 |

|

3 tons ( pneumatic/ Hydraulic ) |

650 × 450 |

10~60 adjustable |

7 |

3 |

Room temperature ~180 adjustable |

0.5~0.6 |

|

5 tons ( pneumatic/ Hydraulic ) |

650 × 450 |

10~60 adjustable |

7 |

5 |

Room temperature ~180 adjustable |

0.5~0.6 |

|

10 tons ( pneumatic/ Hydraulic ) |

700 × 600 |

10~60 adjustable |

8 |

10 |

Room temperature ~180 adjustable |

0.5~0.6 |

|

After saling Pulp molding machine, if necessary, We will send one or two engineers to set up and commissioning of the Pulp molding machine until it running in normal state. Druing the time your workers who will operate the Pulp molding machine will be trained.

|

Chinese

Chinese English

English German

German Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korean

Korean Arabic

Arabic Russian

Russian